This can be anything from creating stylish shoes to trendy jackets, and leather is a universal material that fits well with all. One of the ways to make leather look even more beautiful is a new solution that can be provided by laser cutting technology. This modern technique gives an exceptional option in comparison to outdated carpet, hardwood and ceramic leather block with the ability for complex textures and patterns - all while maintaining its individuality and sophistication.

Using technology like a laser cutting machine, this focused ray of light can be used to cut through the leather with unparalleled accuracy and at remarkable speeds. The finished product is a unique design that brings an impressive level of dimension and texture to the leather, turning it into a piece like no other.

Perhaps the most thrilling part about employing laser cutting technology is how it paves way to making custom designs - which provides leather craftsmen a boundless universe of results. Designs capable of combining the precision that just laser-cutting can provide, and with it breathe life to his imagination in a way never seen before.

Although leather is often thought of as a humble material, it can be transformed into something extraordinary by the introduction of laser cutting technology. This allows for countless design possibilities such as more complexcut-outpatterns and even mimicking lace designs, semi-precious stones textures or super fine intricate curves in custom shapes designed to fit anystyle.

The design potential is endless with laser cutting. Laser cut designs from traditional star, circle and square patterns through to other geometric shapes can deliver the pattern intricacy that could be either used for enhancing different kind of items in your home like decorative pieces or fashion accessory up to a wider use bufioitairo art deco style,getMock-up unit (wooden factory sample), industries etc.

Leather Crafts with Laser Cutting - the Example of Precision and Imagination Classic methods of leather cutting often present challenges that do not exist when laser technology is used, making sure the process goes smoothly by allowing for both exact and creative designs to be cut into the leather.

In addition to significantly reducing the labor involved in creating artistic glass, this new technology enables an incredibly much faster development of large diverse custom designs so artisans can design with freedom that manual cutting cannot match by a long shot. And for those who seek to pique interest in intricate detail, the exacting laser cuts on leather can elevate that sense craftsmanship into new territory.

Laser cutting technology for the leather industry is here to take it into a new age, elevating the limitless potential of design and cut. Craftsmen have this massive canvas of options in front of them to play around with different tools and materials creating magical patterns and shapes.

Beyond the cutting detail, laser-cut leather can be dressed up with bedazzlements such as crystals or stones for that extra touch of je ne sais quoi. The creative opportunities unlocked by laser cutting are endless, with an abundance of patterns and shapes that can be produced using basic tools and a sprinkling of artistic flair.

Of course, laser-cut leather in itself is gorgeous to add to any project but the real labor of love goes into combining it with other finishes and designs. Artisans can take their leather crafting to a whole new level by combining those skills with the laser cutting designs, known especially for uses like grommets, studs and stones while pushing original limitations aside allowing endless possibilities of creativity.

Custom finishes to the leather can add a touch of luxury and increase product value dramatically. From adding cuts to enrich the texture or embroidered surface finishes that augment dimension, all facets of detail contribute to making each handbag personal and distinctive.

On the whole, using laser cutting technology in leather crafts provides an innovative way of making dimension and texture for your designs. When you design and get the patterns laser cut, this not only allows you to be innovative in your designs but also ramps up those leather crafting skills of yours - which is quite rewarding for young crafts enthusiasts looking to take their creative boundaries a notch higher!

Supernova is in a position to accept customer orders in exchange for samples that leather fabric laser cut design, specifications and packaging requirements. Supernova is also able to provide a reliable logistical solution. We can help our customers in choosing the most cost-effective logistic that meets their needs.

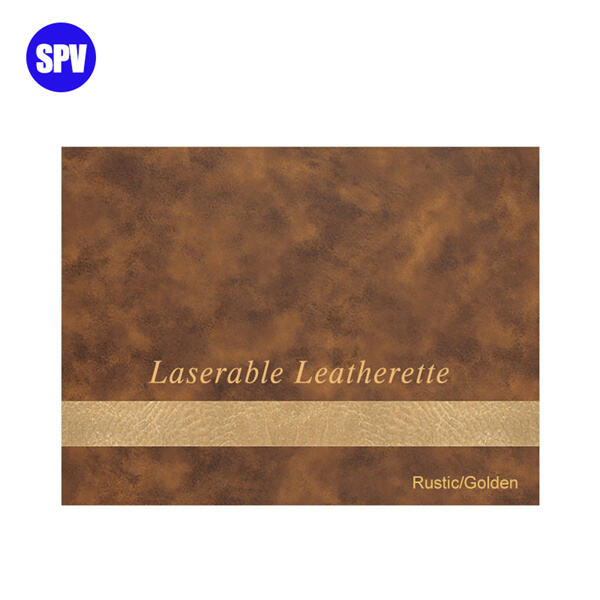

leather fabric laser cut. is a technology development company and distributor of sublimation laser leatherette consumables across the globe. Supernova is a professional 15 years old company, is a renowned market leader for its innovative products in Sublimation Imprinting and Laser. Supernova Systems is a pioneer in the printing using heat and laser sectors. They have invented a myriad of solutions for heat transfer and Laser.

Supernova is a company that specializes in manufacturing sublimation leather and leather fabric laser cut blanks, such as sublimation leather wallets and sublimation leather coasters, sublimation notebooks made of leather, laser leatherette purses with leather, laser cosmetic bags as well as laser leather jewel cases Key chains with laser leather Laser hat patch, laser stickers etc.

Supernova Systems' core mission is to leather fabric laser cut high-quality products that meet and surpass industry standards for graphics and business output solutions. Supernova Digital Science Tech Co., Ltd. Supernova Systems is committed to total customer satisfaction and provides free technical support for all products. In all stages of selection of products as well as post-sales, Supernova Systems offers expert advice, well-informed guidance and superior customer support. Our website is constantly updated to provide you with the latest price list, product information and helpful tips and tricks of the trade.