But did you ever stop to think how these intricate patterns and designs land on the leather products from bags, shoes to belts? Historically, this was done through more traditional means; like stamping and hand carving in-house by your local leather goods craftsman. However, it is Supernova Fiber Laser Technology that is about to usher one of the marvels of today in leather cutting.

After a bright idea is implemented to the area that we want to mark, very powerful light beam realized by fiber optics based technology hits instantly and exact features which have been defined before over leather surface. The new method streamlines the top-quality marking of laser engraving on black leather to ensure manufacturers can create high-grade, bespoke products in a fraction of the time.

Fiber Laser technology has many advantages for leather engraving compared to conventional methods. First and foremost, it gives us the best design we can possibly create. The laser can intricately etch incredibly fine patterns into the leather allowing for rich and detailed images.

Along with better performance than conventional methods fiber laser technology dramatically reduces certain production times. This is particularly interesting in leather and knife industries as time directly means money. Manufacturers are able to reduce their production times when making use of Supernova engraving leather with diode laser technology which as a result increases productivity and profitability.

Now the way of personalization in leather accessories has become different as Fiber laser etching is becoming more reachable everyday. Before these rulings the number of different designs each manufacturer could build was restricted. The almost limitless variety of patterns and designs that fiber laser technology enables designers to produce compared with roll-patterned material.

Now, illustrated options range from intricate florals to strong geometric that are more vivid than they ever were. If you like that bottom level customization and process, there are often many more doors to a truly bespoke entry point into wearing the most comfortable sneakers custom-built for feet of one: everyone in essence really your own logo.

Benefits of fiber laser technology, product quality and aesthetics are improved as well by increasing manufacturing productivity capabilities. The use of fiber laser technology helps to eliminate dependence on labor as a touch-up - manual carving or embossing with the heart decoration process, and has been consumed much in terms of manufacturing time and cost.

Similarly, the capacity to program Supernova fiber laser technology for processing multiple designs at once contributes toward improved efficiency. Manufacturers can now produce more of the finest leather products in a fraction of time embedded and sell them at higher margins that have been developed using this technology.

Leather goods industry now have new creative doors opened through fiber laser technology. No longer restricted to those traditional patterns and designs, fashion designers can now create very intricate individualized patterns that were previously impossible or simply too cost prohibitive.

Fiber laser technology quickly slices through leather to produce a design as well. It does this by moving a laser beam that cuts through the material very rapidly which creates super clean and crisp edges with hyper accuracy. This is especially helpful when dealing with leather, given that some of the higher end products will require more intricate cuts than a simple square.

Therefore, the transformative power of this machine to alter both how leather goods are marked and produced is worthy enough in its own right for us as a company to express an even greater enthusiasm around fiber laser technology. It allow artist to create/design/make beautiful leather goods way quicker - more accurate, precise and specific finishing. This allows more people to choose from a plethora of designs ultimately giving birth to even more individual and personal products. There is an enormous scope of growth, laser engrave faux leather have capture the leather industry and we know you are going to produce new methods for producing innovative design into their products.

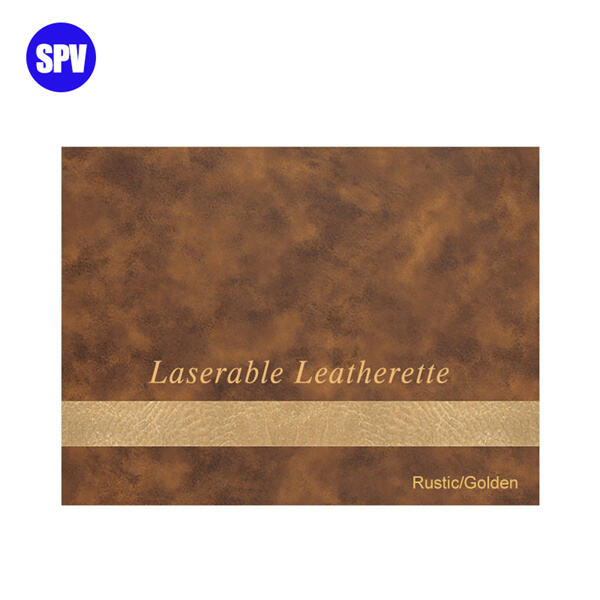

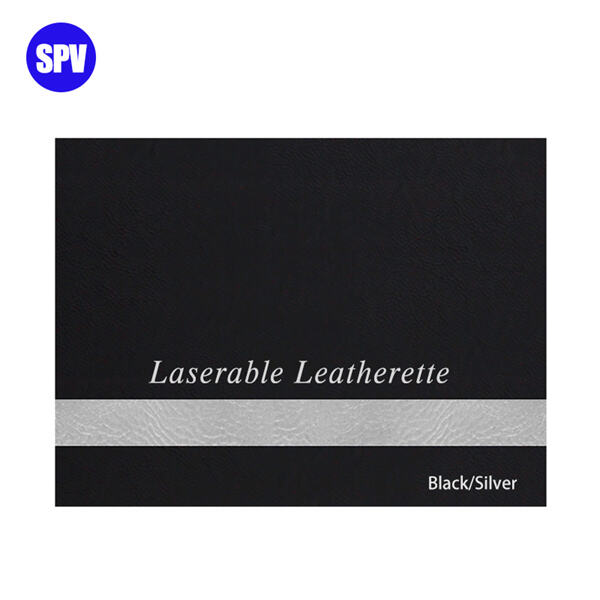

Supernova is a leader in manufacturing sublimation leather blanks and laser Fiber laser leather. Examples include sublimation leather wallets, sublimation leather watchbands, sublimation leather coasters leather notebooks, laser leatherette, laser wallets made of leather, laser cosmetic bags and laser leather jewel cases keys with laser leather and laser hat patches, stickers, etc.

Supernova Systems' core mission is to offer top-quality products that meet or exceed industry standards for graphics and business output solutions. Supernova Digital Science and Technology Co., Ltd. ensures that its customers are satisfied to the Fiber laser leather degree and provides no-cost technical assistance for all products that it sells. During all stages of choosing a product, sales, and post sales, Supernova Systems offers expert information, a well-informed guide, and superior customer support. We constantly update our pages to give you the most current price list, product information and helpful tips and tricks of the trade.

Fiber laser leather. is a technology development company and distributor of sublimation laser leatherette consumables across the globe. Supernova is a professional 15 years old company, is a renowned market leader for its innovative products in Sublimation Imprinting and Laser. Supernova Systems is a pioneer in the printing using heat and laser sectors. They have invented a myriad of solutions for heat transfer and Laser.

Supernova is in a position to accept orders from customers samples with specifications for design, Fiber laser leather and packaging specifications. Supernova can also provide an efficient logistic solution. In line with the varied needs of various clients, we can assist them to select the most efficient logistics.